Martijn Boelhouwer: “In 2022, ARN has achieved a recovery rate of 98.7%, of which 87.2% as recycling and 11.5% through energy recovery or another useful application. This means that in 2022 we will also more than comply with the legal obligation arising from the Management of End-of-Life Vehicles Decree.”

Recyclingpercentage 2022

Contribution to entire chain

Recycling performance in the car recycling chain in 2022 was calculated based on:

- weight statistics and information provided by chain partners on their recycling performance;

- three shredder tests carried out in 2015;

- massabalansgegevens van shredderbedrijven in België en Duitsland.

Substantiation of the realised recycling results

The information that ARN extends is not provided on a completely voluntary basis, continues Boelhouwer. “Every year, the RAI Association commissions us to publish a mandatory report on the realised recycling percentage on behalf of the producers and importers that are affiliated with ARN.” The Inspectie Leefomgeving en Transport (ILT, Environment and Transport Inspectorate) has endorsed the methodology that ARN uses for this purpose and carries out random inspections.

In 2022, for example, the ILT verified the applied methodology, as well as the quality of the data provided by car-dismantling companies, brokers and shredder companies. This ensured that a consistent picture is sketched, thereby guaranteeing that the methodology used by ARN is qualitatively sound and that the results meet the requirements set out by the ELV Directive.

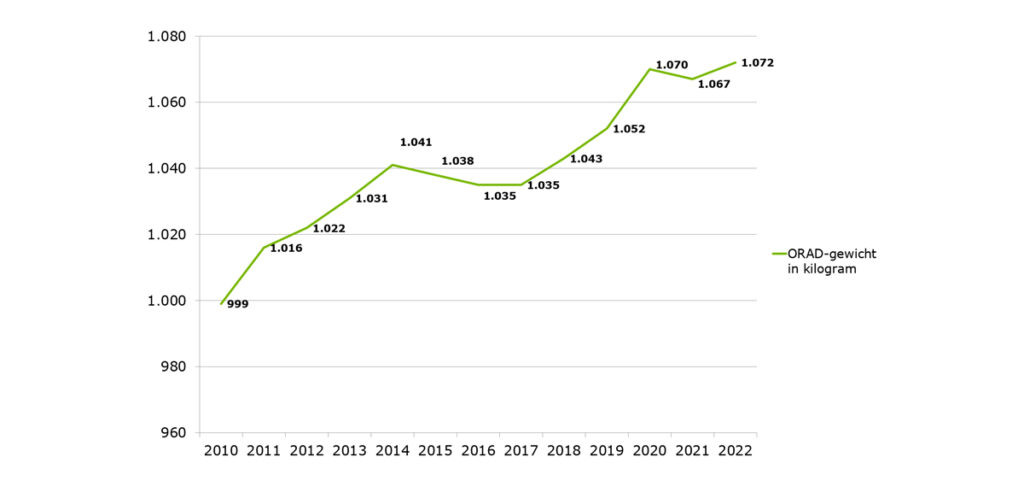

Weight statistics for car-dismantling companies

The calculation of the recycling performance starts with the determination of the average empty weight of all vehicles deregistered for dismantling in 2022 through the Online Auto Dismantling Registration (ORAD) portal. Based on these statistics, the average weight of end-of-life vehicles in 2022 was 1,072kg (marginally up on the 1,067kg in 2021). “During the past 10 years, the average weight of an end-of-life vehicle has increased by almost 100kg.”

Developing ORAD weight in kg

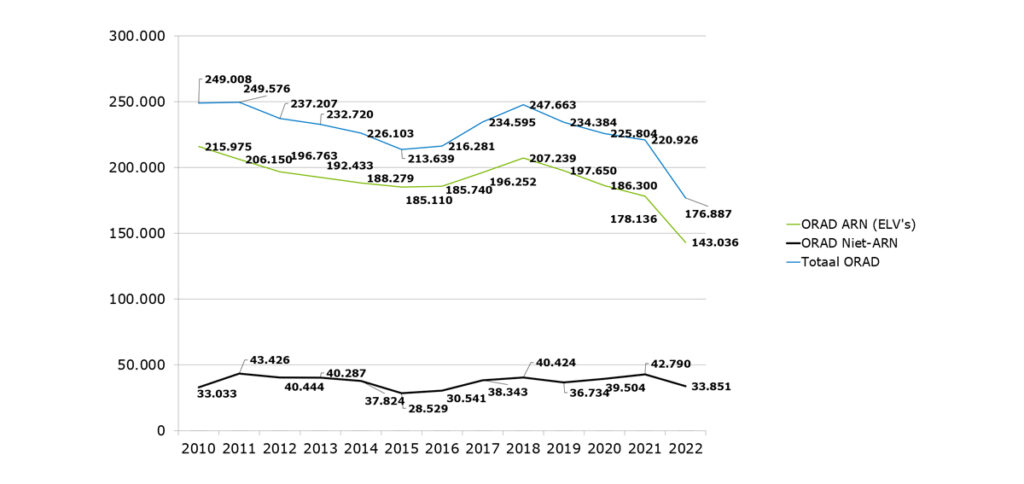

Number of end-of-life vehicles

In 2022, 143,036 end-of-life vehicles were deregistered for dismantling by car-dismantling companies affiliated with ARN (in 2021 it was 178,136). The total number of end-of-life vehicles deregistered in the Netherlands in 2022 was 176,887 (in 2021 it was 220,926). The share of end-of-life-vehicles dismantled by ARN companies increased slightly from 80.6 per cent in 2021 to 80.9 per cent in 2022. “Here in in the Netherlands we have agreed that end-of-life vehicles must be stripped of environmentally hazardous materials, such as fluids and batteries, within 10 working days,” assures Boelhouwer. “Afterwards, they may only remain on the premises of car-dismantling companies for up to three years.”

Developing ORAD ARN and non-ARN

Shredder companies

Eventually, dismantled end-of-life vehicles are transported to shredder companies. . In 2022 the total number was 141,201 (in 2021 it was 197,046). In 2022 the average weight of a dismantled end-of-life vehicle transported to a shredder company was 803kg (in 2021 it was 812kg). By way of explanation Boelhouwer says that the difference between the weight of a vehicle when it is empty and the weight of the same vehicle after being dismantled, is the proportion of the vehicle that is deemed to be recycled by the car-dismantling company. This difference comprises used parts and the materials that have to be mandatorily removed, as well as other materials that are then recycled, such as engine blocks and gearboxes. “In 2022, these totalled 24.9 per cent, slightly more than the 2021 total of 23.7 per cent. This was probably attributable to an increase in the number of large metal parts that were recycled.”

Determining the shredder companies’ share

Shredder companies use ARN’s extranet environment to keep track of how many end-of-life vehicles they receive. Some of these are routed through intermediary traders. The recycling performance of shredder companies is based on the shredder sample-tests that are carried out per company. Given that the average weight of an end-of-life-vehicle shell was less in 2022 than it was in 2021, the share claimed by shredder companies, including the PST plant, dropped slightly in 2022. This share fell from 75 per cent in 2021 to 73.8 per cent in 2022. This percentage comprises 63.1 per cent recycling and 10.7 per cent energy recovery, or other useful applications.

Recyclingpercentage 2022

Contribution per chain partner

Overflow to Belgium and Germany

Shredder companies are capital-intensive organisations, of which there are relatively few in the Netherlands. And it is for this reason that some end-of-life vehicles are also exported. “ARN processes practically all shredder waste from Dutch end-of-life vehicles,” assures Boelhouwer. “End-of-life-vehicles that are processed by foreign shredder companies are reported in the recycling statistics of the relevant destination country.” In 2022, approximately 19 per cent of Dutch end-of-life vehicles were transported across borders to shredder companies in Belgium and Germany. In 2021 it was 25 per cent. For these end-of-life vehicles, ARN bases its reporting on the recycling calculations of the countries in question, from which it requests recycling statements. Of the end-of-life vehicles that end up in shredder companies in the Netherlands, the PST plant in Tiel contributed approximately 18 per cent to the recycling percentage realised in 2022.

Recyclingpercentage 2022

Ratio of Dutch end-of-life cars versus foreign end-of-life cars

Methodology

Among other parameters, the Netherlands bases the calculation of the recycling performance on a shredder test, which is one of the methodologies prescribed by the European Union. European Directive 2000/53/EC forms the basis of the calculation, which documents the processing of end-of-life vehicles and the relevant accountability. The methodology that ARN uses to calculate recycling performance is described in more detail in European Commission Decision 2005/293/EC. The Netherlands has adopted the European guideline and the ensuing stipulations in the End-of-Life Vehicles (ELV) Directive (known in Dutch as the Bba).